|

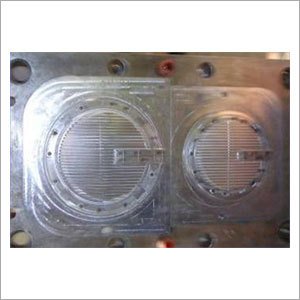

Silicone Ring Multi Cavity

Silicone Ring Multi Cavity Specification

- Technique

- Compression Molding / Liquid Silicone Rubber Processing

- Dimension (L*W*H)

- As per customer requirement or standard sizes (multiple cavities per mold)

- Processing

- Injection Molding

- Surface Treatment

- Smooth finish

- Type

- Multi Cavity Mold

- Material

- Silicone Rubber

- Shaping Mode

- Multi Cavity Mold

- Weight

- Varies as per design and cavity count

- Color

- Customizable (usually red, blue, white, transparent)

About Silicone Ring Multi Cavity

Customizable Multi Cavity Solutions

Whether standard or tailored dimensions are required, our silicone ring multi cavity molds can be crafted to meet your specifications. Each design is engineered with the option for multiple cavities, enabling efficient bulk production of silicone rings. Color and sizing customization are available to suit a variety of applications and industry needs.

Advanced Molding Techniques for Precision

We utilize both injection molding and compression moldingincluding liquid silicone rubber processingto produce highly durable molds. These modern techniques ensure uniformity and quality across every ring produced, while the smooth surface treatment delivers a superior finish ideal for demanding applications.

FAQs of Silicone Ring Multi Cavity:

Q: How are the dimensions for the Silicone Ring Multi Cavity Mold determined?

A: The dimensions for each mold can be customized as per your requirements or selected from standard sizes. We work closely with customers to ensure molds are manufactured exactly to their specifications, optimizing performance and final product quality.Q: What process is used to manufacture the multi cavity molds?

A: Our molds are manufactured using injection molding or compression molding processes, including liquid silicone rubber processing. These advanced techniques guarantee precise, repeatable results, especially for high-volume production.Q: When is a multi cavity mold most beneficial to use?

A: Multi cavity molds are ideal when you need to produce large quantities of silicone rings efficiently. They maximize productivity by enabling the simultaneous molding of multiple rings in a single cycle, reducing time and cost in the manufacturing process.Q: Where are these silicone ring molds commonly used?

A: Silicone ring multi cavity molds are widely used across various industries, including automotive, healthcare, consumer goods, and electronics, wherever durable and high-performance silicone rings are required.Q: What are the benefits of using silicone rubber for these molds?

A: Silicone rubber provides excellent durability, flexibility, and resistance to heat and chemicals. Its properties contribute to long-lasting molds and reliable end products, suitable for demanding environments.Q: Can the color of the silicone rings be customized?

A: Yes, we offer customization in color, with common choices including red, blue, white, and transparent. If you require a specific color, we can accommodate your request based on availability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulds Category

Precision Plastic Mould

Technique : Injection Molding

Type : Plastic Injection Mould

Surface Treatment : Polished, Textured, EDM Finish

Color : Silver, Customized

Dimension (L*W*H) : Customized as per requirement

Shaping Mode : Plastic Injection Mould

Shell Mould

Technique : Sand Casting

Type : Shell Mould

Surface Treatment : Polished

Color : Grey

Dimension (L*W*H) : As per customer requirement

Shaping Mode : Other, Casting Mould

Speaker Grill Mould

Technique : Injection Molding

Type : Plastic Injection Mould

Surface Treatment : Polished, Textured

Color : Customizable (Mould color: Silver/Grey; Product color as per requirement)

Dimension (L*W*H) : Customizable as per requirement

Shaping Mode : Plastic Injection Mould

Plastic Battery Cover Mould

Technique : Precision Moulding

Type : Plastic Mold

Surface Treatment : Polished / Textured

Color : Customizable (Black, Grey, etc.)

Dimension (L*W*H) : Customizable as per battery size

Shaping Mode : Plastic Injection Mould

|

BHARATI TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry