|

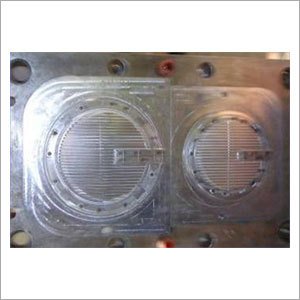

Shell Mould

Shell Mould Specification

- Feature

- High Precision, Durable, Corrosion Resistant

- Surface Treatment

- Polished

- Technique

- Sand Casting

- Processing

- Casting

- Application

- Industrial, Automobile, Machinery Parts

- Dimension (L*W*H)

- As per customer requirement

- Type

- Shell Mould

- Material

- Metal (typically iron, steel, or alloy)

- Shaping Mode

- Casting Mould

- Weight

- Customized

- Color

- Grey

About Shell Mould

Custom Dimensions for Every Requirement

Each Shell Mould we produce is precisely tailored to your required length, width, and height. No two client needs are identical, and our flexible manufacturing process allows for complete customization, ensuring a perfect fit for your industrial, automotive, or machinery component casting needs. We collaborate closely with customers to deliver optimal results.

Advanced Sand Casting Techniques

Utilizing sand casting as our primary technique, we achieve superior detail and consistency in every shell mould. This method maintains the moulds structural strength and surface quality, leading to enhanced performance in demanding industrial applications. Our expertise ensures that even complex shapes are manufactured with accuracy and efficiency.

Built for Strength, Precision, and Durability

Our Shell Moulds are made from robust metals such as iron, steel, or alloys, providing outstanding strength and resistance to corrosion. Every mould is polished for a refined finish and engineered for longevity, making them ideal for high-precision and continual use in manufacturing environments.

FAQs of Shell Mould:

Q: How are Shell Moulds manufactured to meet specific dimensional requirements?

A: Shell Moulds are custom-designed and produced according to the customers specified dimensions (length, width, and height). We use advanced sand casting methods to accurately reproduce complex designs, ensuring every mould matches the clients unique requirements.Q: What materials are used for these Shell Moulds, and why?

A: Our Shell Moulds are typically made from high-quality iron, steel, or alloy metals. These materials are chosen for their strength, durability, and resistance to corrosion, guaranteeing a long-lasting and reliable mould suitable for industrial use.Q: When should I choose a shell mould for my manufacturing processes?

A: Shell Moulds are ideal when high precision, durability, and smooth surface finish are essential. They are particularly beneficial for producing industrial, automobile, and machinery parts where consistent quality and exact tolerances are critical.Q: Where can these Shell Moulds be applied?

A: These Shell Moulds are commonly used in industrial sectors, automotive manufacturing, and machinery parts production. Their robust design and customizability make them suitable for demanding environments requiring precision and repeatability.Q: What is the processing method for these Shell Moulds?

A: The moulds are manufactured using the sand casting process, where a metal shell is formed by pouring molten metal into a mould cavity lined with a sand and resin mixture. This method allows for the creation of complex shapes and fine details.Q: How do Shell Moulds benefit industrial manufacturers?

A: Shell Moulds provide high dimensional accuracy, durability, and a polished finish, resulting in superior end products. Their corrosion resistance and customizability also help reduce downtime and maintenance, making production more efficient.Q: What surface treatment is applied to the Shell Moulds?

A: Each Shell Mould undergoes a polishing treatment to enhance surface smoothness and resist corrosion, ensuring longer life and improved performance in repeated casting cycles.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulds Category

Plastic Mould

Material : Other, Plastic, Steel Core

Color : Steel Grey

Technique : CNC Machining

Type : Injection Mould

Processing : Injection Moulding

Dimension (L*W*H) : 350 x 250 x 200 mm

Precision Plastic Mould

Material : Other, P20, S136, H13, 718 Steel, ABS, PC, PP, PE

Color : Silver, Customized

Technique : Injection Molding

Type : Plastic Injection Mould

Processing : CNC Machining, EDM, Grinding, Drilling

Dimension (L*W*H) : Customized as per requirement

Towing Eye Cover Mould

Material : Other, ABS Plastic / Polypropylene

Color : Black / Grey / Customized

Technique : Precision CNC Machining

Type : Towing Eye Cover Mould

Processing : Injection Moulding

Dimension (L*W*H) : Customized as per vehicle model

DVD Cover Mold

Material : Other, P20 Steel / H13 / S136

Color : Silver / Metallic Gray

Technique : Precision Machining

Type : Plastic Injection Mold

Processing : Injection Molding

Dimension (L*W*H) : 240 mm x 135 mm x 15 mm

|

BHARATI TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry