|

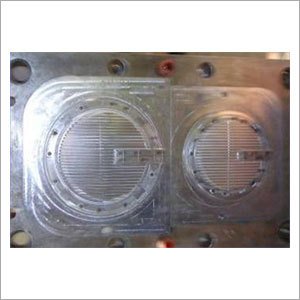

Precision Plastic Mould

Precision Plastic Mould Specification

- Technique

- Injection Molding

- Processing

- CNC Machining, EDM, Grinding, Drilling

- Dimension (L*W*H)

- Customized as per requirement

- Surface Treatment

- Polished, Textured, EDM Finish

- Feature

- High Precision, Durable, Corrosion Resistant

- Application

- Automotive, Electronics, Medical Devices, Industrial Parts

- Type

- Plastic Injection Mould

- Material

- P20, S136, H13, 718 Steel, ABS, PC, PP, PE

- Shaping Mode

- Plastic Injection Mould

- Weight

- As per customized design

- Color

- Silver, Customized

About Precision Plastic Mould

Engineered for High Precision Applications

Our injection moulds are purpose-built with meticulous attention to detail, enabling remarkable dimensional accuracy vital for industries like automotive, medical devices, and electronics. Each product is rigorously crafted using world-class equipment and skilled techniques, ensuring every mould achieves top tolerances and performance.

Extensive Material and Finishing Options

Select from a versatile suite of steelssuch as P20, S136, H13, or 718and approved plastic grades including ABS, PC, PP, and PE. Our finishes range from mirror-polished for optimal smoothness to textured and EDM surfaces for specific application demands, ensuring both function and visual appeal.

Custom Solutions and Global Supply

Every order is tailored to client specifications with customized dimensions, weight, and color. Serving as a reputable manufacturer, exporter, and supplier based in India, we efficiently supply precision plastic moulds worldwide, fulfilling both small-batch and bulk orders with prompt support and reliable delivery.

FAQs of Precision Plastic Mould:

Q: How are custom dimensions for the plastic mould determined?

A: Custom dimensions are established through direct collaboration with the client. After reviewing technical drawings or prototypes, our engineers work with you to finalize the moulds exact length, width, height, and other design features, ensuring the product fits your requirements precisely.Q: What processes are involved in manufacturing these moulds?

A: We use advanced CNC machining, EDM (Electrical Discharge Machining), grinding, and drilling techniques, followed by injection molding to shape and finish each mould. These processes ensure high precision, smooth finishes, and robust durability in the final product.Q: When should I consider using a high-precision plastic mould?

A: High-precision plastic moulds are ideal when your components demand tight tolerances, consistent quality, and excellent durabilitycommon needs in automotive, electronics, medical devices, and industrial equipment manufacturing.Q: Where are your moulds manufactured and supplied from?

A: All our plastic moulds are manufactured in our state-of-the-art facilities in India. We export globally and serve as both a manufacturer and supplier, ensuring reliable international delivery.Q: What materials are available for producing these moulds?

A: We offer a diverse selection of materials, including P20, S136, H13, and 718 steel for moulds, as well as plastic options such as ABS, PC, PP, and PE. Our recommendations are based on your applications specific strength, durability, and chemical resistance requirements.Q: How do I select the right surface treatment for my mould?

A: Surface treatment selectionpolished, textured, or EDM finishdepends on the desired appearance, ease of demoulding, and end-use requirements. Our technical team can advise the optimal surface treatment based on your application and production goals.Q: What are the main benefits of using your precision plastic injection moulds?

A: Our moulds offer high precision, long-lasting durability, and resistance to corrosion. Customization ensures the perfect fit for your application, while advanced manufacturing processes deliver consistent, high-quality results that enhance the efficiency and performance of your production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulds Category

DVD Cover Mold

Color : Silver / Metallic Gray

Type : Plastic Injection Mold

Technique : Precision Machining

Shaping Mode : Plastic Injection Mould

Dimension (L*W*H) : 240 mm x 135 mm x 15 mm

Towing Eye Cover Mould

Color : Black / Grey / Customized

Type : Towing Eye Cover Mould

Technique : Precision CNC Machining

Shaping Mode : Plastic Injection Mould

Surface Treatment : Textured / Polished

Dimension (L*W*H) : Customized as per vehicle model

Speaker Grill Mould

Color : Customizable (Mould color: Silver/Grey; Product color as per requirement)

Type : Plastic Injection Mould

Technique : Injection Molding

Shaping Mode : Plastic Injection Mould

Surface Treatment : Polished, Textured

Dimension (L*W*H) : Customizable as per requirement

Silicone Ring Multi Cavity

Color : Customizable (usually red, blue, white, transparent)

Type : Multi Cavity Mold

Technique : Compression Molding / Liquid Silicone Rubber Processing

Shaping Mode : Other, Multi Cavity Mold

Surface Treatment : Smooth finish

Dimension (L*W*H) : As per customer requirement or standard sizes (multiple cavities per mold)

|

BHARATI TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry