|

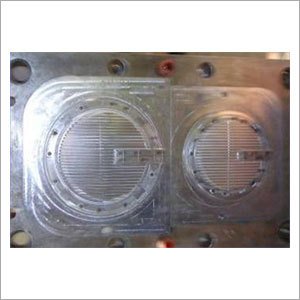

Plastic Battery Cover Mould

Plastic Battery Cover Mould Specification

- Dimension (L*W*H)

- Customizable as per battery size

- Application

- Battery Cover for Automotive, Inverter, Industrial Batteries

- Technique

- Precision Moulding

- Feature

- High Durability, Corrosion Resistant

- Surface Treatment

- Polished / Textured

- Processing

- Injection Moulding

- Type

- Plastic Mold

- Shaping Mode

- Plastic Injection Mould

- Color

- Customizable (Black, Grey, etc.)

About Plastic Battery Cover Mould

Customizable Dimensions for Every Battery

Our battery cover moulds are manufactured to your exact specifications, ensuring a perfect fit regardless of battery size or type. With options for length, width, and height tailored to your needs, our solutions accommodate unique requirements for automotive, inverter, and industrial batteries, providing a seamless production experience each time.

Precision Engineering and Finish

Utilizing advanced injection and precision moulding techniques, we deliver moulds with flawless detail and consistency. Surface treatments like polishing or texturing further enhance the moulds functionality and appearance, ensuring the end product is both attractive and high-performing in diverse environments.

Durable and Corrosion-Resistant Material

Constructed using robust, high-quality plastics, our moulds offer excellent durability and long-term resistance to corrosion. These properties are essential for battery covers, which are often subjected to harsh conditions, ensuring a longer lifespan and secure protection for your batteries.

FAQs of Plastic Battery Cover Mould:

Q: How are the dimensions of the plastic battery cover mould customized?

A: The dimensions of our battery cover moulds are custom-made based on your specific battery size requirements. You simply provide your preferred length, width, and height, and we manufacture the mould accordingly to ensure a precise fit for your application.Q: What is the main manufacturing process used for these moulds?

A: We utilize advanced plastic injection moulding, combined with precision moulding techniques, to ensure each mould is produced accurately and efficiently. This process allows for high-quality, consistent results suitable for a wide range of battery types.Q: When should I consider using a polished versus a textured surface treatment?

A: A polished surface is ideal for producing battery covers with a sleek, smooth finish, while a textured finish adds grip or a distinct appearance. Your choice depends on the functional or aesthetic requirements of your final product.Q: Where are these plastic battery cover moulds primarily applied?

A: These moulds are mainly used in the production of battery covers for automotive, inverter, and industrial batteries, meeting the needs of multiple sectors requiring durable and reliable battery protection.Q: What benefits do your moulds provide compared to traditional moulds?

A: Our plastic battery cover moulds offer high durability, superior corrosion resistance, and customizable sizing and color options, resulting in longer-lasting products that can be tailored to your precise needs.Q: How can I place an order as an international client?

A: As an exporter, manufacturer, and supplier based in India, we efficiently serve domestic and international clients. You can contact us directly with your requirements and dimensions, and we will provide a tailored quote and shipping options.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Moulds Category

Precision Plastic Mould

Technique : Injection Molding

Application : Automotive, Electronics, Medical Devices, Industrial Parts

Type : Plastic Injection Mould

Color : Silver, Customized

Processing : CNC Machining, EDM, Grinding, Drilling

Dimension (L*W*H) : Customized as per requirement

Shell Mould

Technique : Sand Casting

Application : Industrial, Automobile, Machinery Parts

Type : Shell Mould

Color : Grey

Processing : Casting

Dimension (L*W*H) : As per customer requirement

Speaker Grill Mould

Technique : Injection Molding

Application : Speaker grill manufacturing

Type : Plastic Injection Mould

Color : Customizable (Mould color: Silver/Grey; Product color as per requirement)

Processing : CNC Machining, EDM

Dimension (L*W*H) : Customizable as per requirement

Towing Eye Cover Mould

Technique : Precision CNC Machining

Application : Automotive (Front & Rear Bumper)

Type : Towing Eye Cover Mould

Color : Black / Grey / Customized

Processing : Injection Moulding

Dimension (L*W*H) : Customized as per vehicle model

|

BHARATI TECHNOLOGIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry